How Can Standardizing Surgery Tools Prevent Adverse Events?

An interview with Rosemary King, faculty member at Virginia Mason Institute

In your career as the first director of the Kaizen Promotion Office at Virginia Mason, and then a clinical director of perioperative services, how has lean work made a difference to improve patient care?

RK: Soon after we started our lean journey, more than fifteen years ago, Virginia Mason was taking on the translation of the Toyota Production System to health care. In one way, we didn’t know how much work it would take to succeed — we didn’t know what we didn’t know. Some of the improvement team leaders had full-time jobs while they were in training. I was a clinical supervisor but responsible for working with this new team to implement improvement using the Toyota model.

How did you start?

RK: Leadership decided to focus on Perioperative Services. It was such an important area in the hospital — it was a big driver of revenue, with lots of opportunities for improvement. We wanted to do great work, to really blow up the old processes and rebuild them to make care better for patients.

This meant lots of meetings with the surgeons and executive leaders. As we started to fundamentally understand the value stream of the surgical patient, we saw that there were great opportunities for standardization. We knew that standardizing some of the work could help us prevent mistakes from reaching the customers, our patients. We also saw a great opportunity to make immediate improvements in the OR equipment room through 5S.

Did you see that making improvements in the equipment room was related to preventing adverse events?

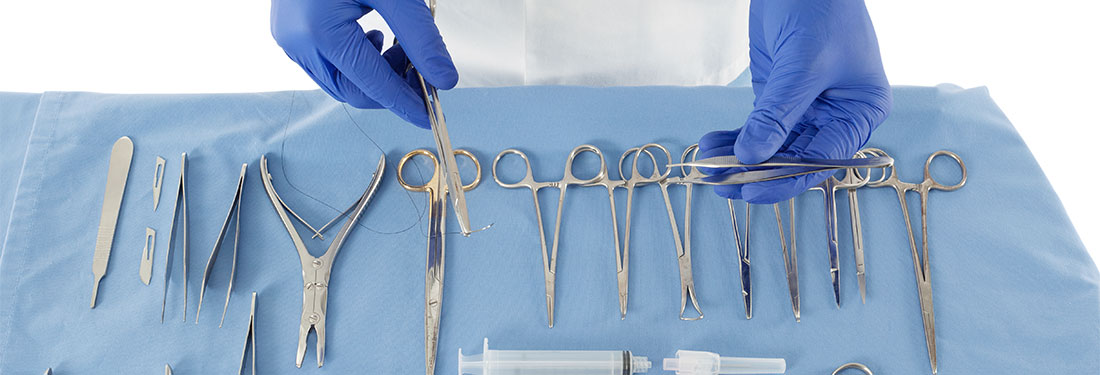

RK: Yes. When we started, there were no standard locations for all the items in the room, and the staff had told us how onerous it was to look through the maze of tools — some of them broken, some of them rarely used — and find just the piece of equipment that particular surgeon might need for an upcoming procedure. We found that the equipment was very expensive and had incredible variation depending on the surgeon who was using it.

We knew from our education at Toyota that variation in processes could lead to errors, and we knew that we could use the principles of 5S (sort, simplify, sweep, standardize and self-discipline) to reduce variation and reduce the burden of work for staff. We followed the same principles in our efforts to standardize the instrument sets used for surgical procedures, and we knew we needed to work with the surgeons to determine how to organize and standardize the incredible number of instruments in the sets.

“We wanted to do great work, to really blow up the old processes and rebuild them to make care better for patients.”

– Rosemary King

How did your improvement team and the surgeons work together to standardize the instrument sets?

RK: We started by analyzing a high-volume procedure, the laparoscopic cholecystectomy. When we looked into it, we saw that different physicians used different tools for the very same procedure. So to get people on the same page, the improvement team created a matrix to show the incredible variation of the tools and supplies that the different surgeons used for the laparoscopic cholecystectomy. It was a huge matrix that we put on the wall, and the surgeons found it fascinating to see the variation between physicians.

It helped to engage the physicians in the improvement work, to create a compelling reason for change and to create understanding. At one point we were discussing the use of disposables versus reusable equipment, with different surgeons weighing in on which was better. One said that he used disposables because they were sharper. The team asked, “What if we could find a reusable tool that was just as sharp as the disposable tool?” We didn’t want to sacrifice quality, and at the same time we wanted to reduce the variation. The surgeons and everyone involved in the improvement work knew this.

These discussions helped everyone understand the surgeons’ behavior. Before the lean improvement meetings, the surgeons were disconnected from what happened to the tools before and after they used them. The RPIWs (Rapid Process Improvement Events) opened their eyes to the burden of work on their teams — all of the hours that staff spent assembling, sorting, transporting, and then reprocessing these instruments. And many of these tools were never or rarely used during procedures, even if they were brought into the OR.

Did the physicians start to think differently about which tools they used?

RK: Yes. Really, they were fascinated to see all the instruments and supplies we had on hand for their procedures. We needed to sort the necessary from the unnecessary to move this work forward. Sometimes the sort was quick, easy and logical. Other times, unpredictably, there would be some sensitive issues, some emotional attachment to certain tools. Everyone had to be able to compromise, to think about the connection to patient care and patient safety and to choose which hill to die on. In the end, it helped to change what instruments and supplies physicians asked for. Everyone in the event learned to appreciate each other and felt valued for their role in the improvements.

Why did people feel this sense of appreciation?

RK: We all had the same goals. We wanted to make progress. We wanted to make things more efficient for the staff and the surgeons. We also knew that variation contributes to errors which can impact patient safety. Standardizing the equipment and instruments helped to make sure we had what we needed when we needed it, which enhanced patient safety. We wanted to mistake-proof the process so that adverse events wouldn’t happen to our patients.

Did this early work for standardizing the laparoscopic cholecystectomy procedures become the model for other standardization efforts?

RK: It did, and we kept improving the processes incrementally. We used the 5S principles for the standardization of implants for spine and orthopedic procedures. We knew that there were many vendors with wonderful products for spine and total joint procedures. We also knew that we needed to buy the highest-quality products available for everyone involved, and to buy them in volumes. That way, we could be confident about the quality for our patients and get a tremendous price break with the volume discounts. Having tiny amounts of various products didn’t make sense for patients, surgeons or staff — in terms of quality or costs.

Do you have advice for improvement teams in other organizations?

RK: Involving the people who do the work in improvement efforts demonstrates respect for their expertise and understanding of the processes in focus. An engaged staff can move mountains.